On minimum number of component systems every detail can make much difference.

If the signal levels involved are low and the microphone head amplifier is ultra low noise, analytical a change in input circuit resistance will manifest as increase in thermal noise or hiss.

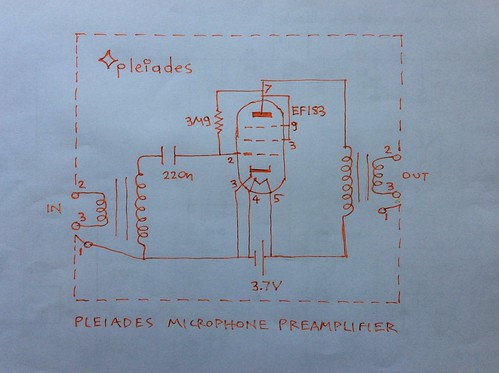

Such is the case for example with the Pleiades V6 battery powered electron tube head amplifier. If cables are reinserted to the breadboard a small hiss can be heard to decrease.

A small problem in any contact including batteries can be heard as a very loud noise.

At the moment it is in breadboard stage and a problem in the 200 Ω input cabling will increase thermal noise or hiss.

Microphone plug and socket contacts should kept very clean. The Pleiades V6 should be built in a hard wired experiment box even perhaps before moving to the octagon Hammond orange aluminum die cast box.

Should barrier strip be used for the mic input terminals having resistance tending to 0Ω or a clean Neutrik XLR?

On noisy amplifiers these effects many not be heard as they are covered by the noise.

Would the Pleiades V6 sound even less noise when hard wired? Either Nuvistor 7586 or EF183 will be used. See previous posts.

No comments:

Post a Comment